We use a combination of printing methods dependent on the job. Whether it’s a smaller or larger run will depend on what printing process is used to ensure it’s printed in the most cost effective way.

Various factors are taken into account when considering which printing processes to use. These include the quantity needed, the format of print, the stock it will be printed on and the requested turnaround time – using these factors, we can decide which method best suits each job.

Typically, the two main methods of printing used at Henry Christopher are lithographic print and digital print.

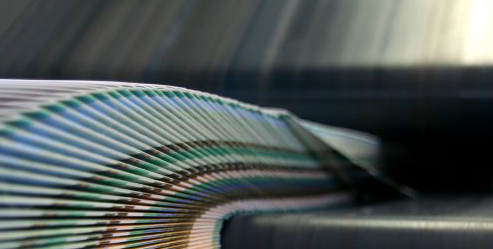

Lithographic Printing

Lithographic printing involves the use of plates which are made using a machine that exposes light to the plate, using lasers directly from the computer that creates a photographic negative of the desired image. The plates are coated with a photosensitive emulsion. The emulsion is then chemically treated to remove the unexposed portions of the emulsion. This final step is similar to developing film at a photo lab.

On the press, the plate comes into contact with the ink coated roller, which adheres to the smooth, or positive portions of the image. The plate is then rolled over a blanket (a cylinder covered with rubber) which picks up the ink and then the cylinder is rolled over the paper creating the desired image.

Digital Printing

Digital printing involves assembling each image from a complex set of numbers and mathematical formulas. These images are captured from a matrix of dots called pixels, this process is called digitising.

This image is then used to digitally control the deposition of ink, toner or exposure to light, to reproduce the images. The colour management system helps to keep images looking the same crisp colour despite where they are viewed or printed.

One of the most important advantages of digital printing is the quick response time due to its minimal setup and it’s built in multi-colour registration system. Another advantage of digital printing is the ability to personalise and customise orders, which means that each printed piece can have different information on it.

Which One to Choose?

Depending on which method of print suits a job mainly depends on the size and quantity of the print run.

Lithographic jobs are more suited to longer print jobs, for example, batches of a thousand plus in quantity. This is due to the set-up and management of the machine during the print run.

Digital is better suited to smaller run jobs, for example, batches of hundreds in quantity. Set up of the machine is minimal and electronic.

The good news is that the quality and finish of both a lithographic job and a digital job is that they are both comparable. Due to technological advances of digital printers, the quality, colours and tones of a digital print run means that they equal the quality of a lithographic print run.

We are committed to ensuring the highest quality and most cost effective price for your printing.

Once your order is placed, our expert team will determine which process will best suit your job.